3D bioprint: Versiyalar orasidagi farq

k Gayratjon vohidov tahrirlari MalikxanBot versiyasiga qaytarildi Teg: Eski holiga qaytarish |

Tahrir izohi yoʻq |

||

| Qator 1: | Qator 1: | ||

[[File:Advs2797-fig-0001-m.jpg|thumb|Different models of 3D printing tissue and organs.|350x350px]] |

|||

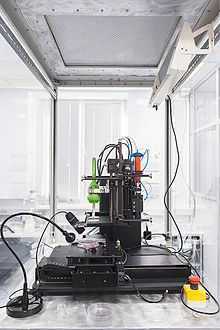

{{xatolar}}{{wikify}}[[Fayl:Printer_3D_Bioprinting_Solutions.jpg|thumb|3D-bioprinter]] |

|||

'''Uch o'lchovli (3D) bioprinting''' - ko'pincha tabiiy to'qimalarning xususiyatlarini taqlid qilish maqsadida biotibbiy qismlarni ishlab chiqarish uchun hujayralarni, o'sish omillarini va/yoki biomateriallarni birlashtirish uchun 3D bosib chiqarishga o'xshash usullardan foydalanish. Umuman olganda, 3D bioprinting bio-siyoh deb nomlanuvchi materiallarni to‘ldirish uchun qatlam-qatlam usulidan foydalanib, keyinchalik turli tibbiyot va to‘qima muhandisligi sohalarida qo‘llaniladigan to‘qimalarga o‘xshash tuzilmalarni yaratishi mumkin. 3D bioprinting bioprinting texnikasi va biomateriallarning keng doirasini qamrab oladi. Hozirda bioprinting yordamida dori va potentsial muolajalarni tadqiq qilishda to‘qima va organ modellarini chop etish mumkin. Shunga qaramay, bioprinted tirik hujayra konstruksiyalarini klinik qo'llashga tarjima qilish funktsional organlarni yaratish uchun zarur bo'lgan murakkablik va hujayralar soni tufayli bir qancha muammolarga duch keladi. Biroq, innovatsiyalar hujayradan tashqari matritsaning bioprintsiyasidan tortib, kerakli to'qimalarni hosil qilish uchun qatlam bo'ylab yotqizilgan gidrogellar bilan hujayralarni aralashtirishgacha davom etadi. Bundan tashqari, 3D bioprinting iskalalarni bosib chiqarishni o'z ichiga boshladi. Bu iskalalardan bo'g'inlar va ligamentlarni qayta tiklash uchun foydalanish mumkin.<ref>{{cite journal | vauthors = Nakashima Y, Okazak K, Nakayama K, Okada S, Mizu-uchi H | title = Bone and Joint Diseases in Present and Future | journal = Fukuoka Igaku Zasshi = Hukuoka Acta Medica | volume = 108 | issue = 1 | pages = 1–7 | date = January 2017 | pmid = 29226660 }}</ref> |

|||

'''3D-'''bioprinting — bu hujayralar funktsiyalari va hayotiyliginii<ref>{{Yangiliklar manbasi|title=Research into 3D-Bioprinting may soon produce transplantable human tissues|url=http://www.3ders.org/articles/20140306-research-into-3d-bioprinting-may-soon-produce-transplantable-human-tissues.html|publisher=3ders.org|date=2014-03-06|accessdate=2019-05-14|lang=en|archivedate=2020-01-24|archiveurl=https://web.archive.org/web/20200124231437/http://www.3ders.org/articles/20140306-research-into-3d-bioprinting-may-soon-produce-transplantable-human-tissues.html}}</ref> saqlaydigan 3D bosib chiqarishdan foydalangan holda hujayra asosida uch oʻlchovli modellarni yaratish texnologiyasi. Ushbu texnologiya bilan bogʻliq birinchi patent 2003-yilda [[Amerika Qoʻshma Shtatlari|AQShda]] topshirilgan va 2006-yilda olingan<ref>[http://worldwide.espacenet.com/publicationDetails/biblio?CC=US&NR=7051654&KC=&FT=E&locale=en_EP Bibliographic data: US2004237822 (A1) ― 2004-12-02]</ref>. |

|||

== |

==Jarayon== |

||

[[File:Bioprinting-of-3D-Convoluted-Renal-Proximal-Tubules-on-Perfusable-Chips-srep34845-s3.ogv|thumb|right|Bioprinting of 3D Convoluted Renal Proximal Tubules on Perfusable Chips]] |

|||

Aslida biologik tuzilmalarni ishlab chiqarish uchun 3D bioprint texnologiyasi biologik toʻqimalarning uch oʻlchovli tuzilmalarini yaratishda qatlam-qatlam usulidan foydalangan holda hujayralarni biomoslashuvchan asosda joylashtirishni oʻz ichiga oladi. Tanadagi toʻqimalar har xil turdagi hujayralardan tashkil topganligi sababli 3D bioprint texnologiyalari ham hujayra barqarorligi va hayotiyligini taʼminlash qobiliyati bilan sezilarli darajada farqlanadi. 3D bioprintingda qoʻllaniladigan baʼzi usullar[[fotolitografiya]], magnit bioprint, stereolitografiya va toʻgʻridan-toʻgʻri hujayra ekstruziyasi kabilardir. Bioprinterda ishlab chiqarilgan hujayrali material inkubatorga oʻtkaziladi va u yerda yana oʻstiriladi. |

|||

33D bioprinting odatda uchta bosqichdan iborat: bioprintingdan oldingi, bioprinting va post-bioprinting.[7][8]<ref name=":02">{{cite journal | vauthors = Shafiee A, Atala A | title = Printing Technologies for Medical Applications | journal = Trends in Molecular Medicine | volume = 22 | issue = 3 | pages = 254–265 | date = March 2016 | pmid = 26856235 | doi = 10.1016/j.molmed.2016.01.003 }}</ref><ref name=":1">{{cite journal | vauthors = Ozbolat IT | title = Bioprinting scale-up tissue and organ constructs for transplantation | journal = Trends in Biotechnology | volume = 33 | issue = 7 | pages = 395–400 | date = July 2015 | pmid = 25978871 | doi = 10.1016/j.tibtech.2015.04.005 }}</ref> |

|||

== Amalga oshirish == |

|||

[[Fayl:3D-биопринтер_(2021).jpg|left|thumb|200x200px|<center><small>Twins Garden restoranida 3D bioprinterda kalamar ishlab chiqarish</small></center>]] |

|||

Ekspertlar fikrlariga koʻra San-Diyegoda joylashgan[[San Diego|Organovo]] kompaniyasi 3D bioprinting texnologiyasini tijoratlashtirgan birinchi kompaniyadir.<ref>{{Статья}}{{Статья|автор=Ken Doyle|заглавие=Bioprinting: From Patches to Parts|ссылка=http://online.liebertpub.com/doi/abs/10.1089/gen.34.10.02|язык=|издание=Genetic Engineering & Biotechnology News|тип=|год=2014-05-14|месяц=|число=|том=34|выпуск=10|номер=|страницы=1, 34—35|issn=1935-472X|doi=10.1089/gen.34.10.02}}</ref> Kompaniya NovoGen MMX Bioprinter 3D bioprinterlaridan foydalanadi.<ref>{{veb manbasi |author=Steven Leckart |url=https://www.popsci.com/technology/article/2013-07/how-it-works-3-d-printer-liver-tissue/ |title=How It Works: A 3-D Printer For Liver Tissue |website=[[Popular Science]] |date=2013-09-19 |access-date=2021-05-22 |archive-date=2021-05-22 |archive-url=https://web.archive.org/web/20210522050651/https://www.popsci.com/technology/article/2013-07/how-it-works-3-d-printer-liver-tissue/ |deadlink=no }}</ref> Orgonovo tomonidan qoʻllangan 3D printerlar jarrohlik va transplantatsiya uchun kerak boʻladigan [[teri]], [[yurak]], [[qon tomirlari]] va boshqa [[transplantatsiya]] toʻqimalarni yaratish uchun moʻljallangan. |

|||

=== Bioprintingga tayyorgarlik === |

|||

Buyuk Britaniyadagi Suonsi universiteti tadqiqot guruhi rekonstruktiv jarrohlikda foydalanish uchun yumshoq toʻqimalar va sunʼiy [[suyak]]larni ishlab chiqarish uchun 3D bioprinting usullaridan foydalanmoqda.<ref>{{veb manbasi |url=http://www.engineering.com/3DPrinting/3DPrintingArticles/ArticleID/7379/Engineering-Ourselves-The-Future-Potential-Power-of-3D-Bioprinting.aspx |author=Dan Thomas |title=Engineering Ourselves — The Future Potential Power of 3D-Bioprinting |publisher=engineering.com |date=2014-03-14 |accessdate=2019-05-14 |lang=ru |archive-date=2019-06-03 |archive-url=https://web.archive.org/web/20190603221650/https://www.engineering.com/3DPrinting/3DPrintingArticles/ArticleID/7379/Engineering-Ourselves-The-Future-Potential-Power-of-3D-Bioprinting.aspx |deadlink=no }}</ref> |

|||

Oldindan bioprinting bu printer keyinchalik yaratadigan modelni yaratish va foydalaniladigan materiallarni tanlash jarayonidir. Birinchi qadamlardan biri organning biopsiyasini olishdir. Bioprinting uchun ishlatiladigan umumiy texnologiyalar kompyuter tomografiyasi (KT) va magnit-rezonans tomografiya (MRI). Qatlam-qatlam yondashuvi bilan chop etish uchun tasvirlarda tomografik rekonstruksiya amalga oshiriladi. Endi 2D tasvirlar keyinchalik tayyorlanish uchun printerga yuboriladi. Tasvir yaratilgandan so'ng, ma'lum hujayralar ajratiladi va ko'paytiriladi.[7] Keyin bu hujayralar kislorod va boshqa oziq moddalar bilan ta'minlaydigan maxsus suyultirilgan material bilan aralashtiriladi. Ba'zi jarayonlarda hujayralar diametri 500 mkm bo'lgan hujayrali sferoidlar bilan qoplangan. Hujayralarning bunday yig'indisi iskala talab qilmaydi va ekstruziya kabi jarayonlar uchun quvur shaklidagi to'qimalarning sinteziga joylashtirish uchun talab qilinadi.[9]: 165 <ref name="ChuaBio14">{{cite book|url=https://books.google.com/books?id=nhK3CgAAQBAJ|title=Bioprinting: Principles and Applications| vauthors = Chua CK, Yeong WY |publisher=World Scientific Publishing Co|year=2015|isbn=9789814612104|location=Singapore}}</ref>{{rp|165}} |

|||

=== Bioprintlash === |

|||

3D bioprinting texnologiyasining eng ajoyib namoyishlaridan biri 2011-yilda[[TED]]-2011 konferensiyasida amerikalik jarroh va bioinjener Entoni Atala nutqi chogʻida maxsus 3D-printer inson buyragi maketini yaratganida boʻlib oʻtdi.<ref>{{veb manbasi|url=https://www.ted.com/talks/anthony_atala_printing_a_human_kidney?language=ru#t-694949|title=Энтони Атала: Печатая человеческую почку|author=|website=|date=March 2011|publisher=|access-date=2017-10-04|archive-date=2017-07-11|archive-url=https://web.archive.org/web/20170711214302/https://www.ted.com/talks/anthony_atala_printing_a_human_kidney?language=ru#t-694949|deadlink=no}}</ref> |

|||

Ikkinchi bosqichda bioinks deb nomlanuvchi hujayralar, matritsalar va ozuqa moddalarining suyuq aralashmasi printer kartrijiga joylashtiriladi va bemorlarning tibbiy skanerlari yordamida biriktiriladi.[10] Bioprinted oldingi to'qima inkubatorga o'tkazilganda, bu hujayraga asoslangan oldingi to'qima to'qimaga aylanadi. |

|||

Biologik konstruksiyalarni ishlab chiqarish uchun 3D bioprinting odatda to‘qimalarga o‘xshash uch o‘lchamli tuzilmalarni yaratish uchun ketma-ket qatlam-qatlam yondashuvidan foydalangan holda hujayralarni biomos keluvchi iskala ustiga tarqatishni o‘z ichiga oladi.[11] 3D bioprinting yordamida yaratilgan jigar va buyraklar kabi sunʼiy organlarda qon tomirlari, siydik toʻplash uchun naychalar va bu organlar uchun zarur boʻlgan milliardlab hujayralar oʻsishi kabi tanaga taʼsir qiluvchi muhim elementlar yoʻqligi koʻrsatilgan. Ushbu komponentlarsiz tananing asosiy oziq moddalari va kislorodni ichki qismiga chuqurroq olish imkoni yo'q.[11] Tanadagi har bir to'qima tabiiy ravishda turli xil hujayra turlaridan iborat ekanligini hisobga olsak, bu hujayralarni bosib chiqarish uchun ko'plab texnologiyalar ishlab chiqarish jarayonida hujayralarning barqarorligi va hayotiyligini ta'minlash qobiliyatiga qarab farqlanadi. Hujayralarni 3D bioprinting uchun ishlatiladigan ba'zi usullar fotolitografiya, magnitli 3D bioprinting, stereolitografiya va to'g'ridan-to'g'ri hujayra ekstruziyasi.[9]: 196.<ref name="harmon2013">{{cite journal |url=https://bioengineering.rice.edu/uploadedFiles/Bioengineering/The_Big_Picture/scientificamerican0413-54.pdf |title=A sweet solution for replacing organs |journal=Scientific American | vauthors = Harmon K |volume=308 |issue=4 |pages=54–55 |year=2013 |doi=10.1038/scientificamerican0413-54 |access-date=17 February 2016 |archive-url=https://web.archive.org/web/20160217174416/https://bioengineering.rice.edu/uploadedFiles/Bioengineering/The_Big_Picture/scientificamerican0413-54.pdf |archive-date=2016-02-17 |url-status=dead |bibcode=2013SciAm.308d..54H }}</ref> Artificial organs such as livers and kidneys made by 3D bioprinting have been shown to lack crucial elements that affect the body such as working blood vessels, tubules for collecting urine, and the growth of billions of cells required for these organs. Without these components the body has no way to get the essential nutrients and oxygen deep within their interiors.<ref name="harmon2013" /> Given that every tissue in the body is naturally composed of different cell types, many technologies for printing these cells vary in their ability to ensure stability and viability of the cells during the manufacturing process. Some of the methods that are used for 3D bioprinting of cells are [[photolithography]], [[magnetic 3D bioprinting]], [[stereolithography]], and direct cell extrusion.<ref name="ChuaBio14" />{{rp|196}} |

|||

2017-yilda Xitoyda tugʻma quloq nuqsoni boʻlgan bolalarga 3D bosilgan quloqlar koʻchirib oʻtkazildi.<ref>{{Статья|заглавие=In Vitro Regeneration of Patient-specific Ear-shaped Cartilage and Its First Clinical Application for Auricular Reconstruction|ссылка=https://www.ebiomedicine.com/article/S2352-3964(18)30016-1/fulltext|издание=EBioMedicine|год=2018-02|archivedate=2019-05-31|archiveurl=https://web.archive.org/web/20190531142010/https://www.ebiomedicine.com/article/S2352-3964(18)30016-1/fulltext}} DOI: https://doi.org/10.1016/j.ebiom.2018.01.011</ref> |

|||

=== Bioprintlashdan keyin === |

|||

Rossiyada gastronomiya sohasida 3D bioprinter texnologiyalari oshpazlar Anatoliy va Ivan Berezutskiylar tomonidan qoʻllanilgan.<ref>{{veb manbasi |author=Алла Храбрых |url=https://kp.vedomosti.ru/gourmet/article/2020/11/14/846964-napechataite-mne-sup |title=Напечатайте мне суп, или фуд-революция в России |date=2020-11-19 |website=[[Ведомости]] |accessdate=2021-02-22 |archive-date=2020-12-02 |archive-url=https://web.archive.org/web/20201202075028/https://kp.vedomosti.ru/gourmet/article/2020/11/14/846964-napechataite-mne-sup |deadlink=no }}</ref> |

|||

Ikkinchi bosqichda bioinks deb nomlanuvchi hujayralar, matritsalar va ozuqa moddalarining suyuq aralashmasi printer kartrijiga joylashtiriladi va bemorlarning tibbiy skanerlari yordamida biriktiriladi.[10] Bioprinted oldingi to'qima inkubatorga o'tkazilganda, bu hujayraga asoslangan oldingi to'qima to'qimaga aylanadi. |

|||

Biologik konstruksiyalarni ishlab chiqarish uchun 3D bioprinting odatda to‘qimalarga o‘xshash uch o‘lchamli tuzilmalarni yaratish uchun ketma-ket qatlam-qatlam yondashuvidan foydalangan holda hujayralarni biomos keluvchi iskala ustiga tarqatishni o‘z ichiga oladi.[11] 3D bioprinting yordamida yaratilgan jigar va buyraklar kabi sunʼiy organlarda qon tomirlari, siydik toʻplash uchun naychalar va bu organlar uchun zarur boʻlgan milliardlab hujayralar oʻsishi kabi tanaga taʼsir qiluvchi muhim elementlar yoʻqligi koʻrsatilgan. Ushbu komponentlarsiz tananing asosiy oziq moddalari va kislorodni ichki qismiga chuqurroq olish imkoni yo'q.[11] Tanadagi har bir to'qima tabiiy ravishda turli xil hujayra turlaridan iborat ekanligini hisobga olsak, bu hujayralarni bosib chiqarishning ko'plab texnologiyalari biologik materialdan barqaror strukturani yaratish uchun bioprintingdan keyingi jarayon davomida hujayralarning barqarorligi va hayotiyligini ta'minlash qobiliyatiga ko'ra farqlanadi. . Agar bu jarayon yaxshi saqlanmasa, 3D bosilgan ob'ektning mexanik yaxlitligi va funksiyasi xavf ostida.[7] Ob'ektni ushlab turish uchun ham mexanik, ham kimyoviy stimulyatsiya kerak. Ushbu stimulyatsiyalar to'qimalarning qayta tuzilishi va o'sishini nazorat qilish uchun hujayralarga signallarni yuboradi. Bundan tashqari, so'nggi ishlanmalarda bioreaktor texnologiyalari[12] to'qimalarning tez pishishiga, to'qimalarning tomirlanishiga va transplantatsiyadan omon qolish qobiliyatiga imkon berdi.[8] |

|||

== Qiymati == |

|||

3D — bioprinting texnologiyasini ishlab chiqish organlarni etishtirish va innovatsion materiallarni, birinchi navbatda. 3D — bioprinting tomonidan ishlab chiqarilgan toʻqimalar, dorilar (kelajakda-butun organlar) kelajakda tabiiy organlardan ustun boʻlgan xususiyatlarga ega boʻlgan baʼzi hollarda inson organlarining „tabiiy“ oʻrnini bosuvchi vazifasini bajarishi mumkin. Misol uchun, [[Alginat kislota|alginik kislota]] ishlab chiqarish hozirda qizil yosunlardan olinadi va baʼzilaridan ustundir <sup class="" style="white-space: nowrap">]</sup> inson tanasining tabiiy „moddiy“ parametrlari<ref>{{veb manbasi |

|||

|url = https://www.asme.org/engineering-topics/articles/bioengineering/creating-valve-tissue-using-3d-bioprinting |

|||

|title = Creating Valve Tissue Using 3D Bioprinting |

|||

|author = Mark Crawford |

|||

|publisher = ASME |

|||

|date = 2013-05 |

|||

|accessdate = 2019-05-14 |

|||

|lang = ru |

|||

|archiveurl = https://web.archive.org/web/20181021203215/https://www.asme.org/engineering-topics/articles/bioengineering/creating-valve-tissue-using-3d-bioprinting |

|||

|archivedate = 2018-10-21 |

|||

|deadlink = no |

|||

}}</ref>, va polietilen glikol. |

|||

Bioreaktorlar ozuqa moddalarini konvektiv tashishda, mikrogravitatsiya muhitini yaratishda, eritmaning hujayralar bo'ylab oqib ketishiga olib keladigan bosimni o'zgartirishda yoki dinamik yoki statik yuklash uchun siqishni qo'shishda ishlaydi. Har bir turdagi bioreaktorlar har xil turdagi to'qimalar uchun idealdir, masalan, siqish bioreaktorlari xaftaga to'qimalari uchun idealdir.[9]: 198 he ishlab chiqarish jarayoni. Hujayralarni 3D bioprinting uchun ishlatiladigan ba'zi usullar fotolitografiya, magnitli 3D bioprinting, stereolitografiya va to'g'ridan-to'g'ri hujayra ekstruziyasi.[9]: 196.<ref name="ChuaBio14" />{{rp|198}} |

|||

Rossiyada, uch oʻlchamli organ biopechati sohasida faoliyat xususiy laboratoriya, " 3D Biyoprinting Solyushens " Rossiya biyoprinter ''fabion'' organ qalqonsimon dizayn yordamida chop etilgan sichqoncha naql eksperiment natijalarini eʼlon qildi. Keyingi bir necha oy ichida „konstruktsiyalar ildiz otgan va ularning hayotiyligini isbotlagan“.<ref>{{Статья|автор= Bulanova E. A., Kudan E. V. et al. |заглавие=Bioprinting of a functional vascularized mouse thyroid gland construct |ссылка=http://iopscience.iop.org/article/10.1088/1758-5090/aa7fdd/meta;jsessionid=DB24313BD9CDEC8B00A4A62177D36E29.c2.iopscience.cld.iop.org|издание=Biofabrication|год= 2017-08-18|номер= 9(3)}} DOI: https://doi.org/10.1088/1758-5090/aa7fdd</ref> Bioprinter inson qalqonsimon bez va xaftaga toʻqima<ref>{{veb manbasi|url=https://ria.ru/20181205/1543697502.html|title=Российский биопринтер впервые в истории напечатал орган в космосе|author=|date=2018-12-05|publisher=РИА Новости|access-date=2018-12-26|archive-date=2018-12-25|archive-url=https://web.archive.org/web/20181225155033/https://ria.ru/20181205/1543697502.html|deadlink=no}}</ref><ref>{{veb manbasi|url=https://www.interfax.ru/russia/642451|title=Российский биопринтер на МКС распечатал человеческие ткани|author=|website=|date=2018-12-15|publisher=Интерфакс|access-date=2018-12-26|archive-date=2018-12-26|archive-url=https://web.archive.org/web/20181226071258/https://www.interfax.ru/russia/642451|deadlink=no}}</ref> ega boʻldi. |

|||

== |

== Bioprintlash yondashuvi == |

||

Ushbu sohadagi tadqiqotchilar tegishli biologik va mexanik xususiyatlarga ega bo'lgan tirik organlarni ishlab chiqarish uchun yondashuvlarni ishlab chiqdilar. 3D bioprinting uchta asosiy yondashuvga asoslanadi: biomimikriya, avtonom o'z-o'zini yig'ish va mini-to'qimalarni qurish bloklari.[13]<ref name=Murphy>{{cite journal | vauthors = Murphy SV, Atala A | title = 3D bioprinting of tissues and organs | journal = Nature Biotechnology | volume = 32 | issue = 8 | pages = 773–85 | date = August 2014 | pmid = 25093879 | doi = 10.1038/nbt.2958 | s2cid = 22826340 }}</ref> |

|||

{{Manbalar}} |

|||

== |

=== Biomimikriya=== |

||

Bioprintingning birinchi yondashuvi biomimikriya deb ataladi. Ushbu yondashuvning asosiy maqsadi inson tanasidagi to'qimalar va organlarda mavjud bo'lgan tabiiy tuzilishga o'xshash uydirma tuzilmalarni yaratishdir. Biomimikriya organlar va to'qimalarning shakli, ramkasi va mikro muhitini takrorlashni talab qiladi.[14] Bioprintingda biomimikriyani qo'llash organlarning bir xil hujayrali va hujayradan tashqari qismlarini yaratishni o'z ichiga oladi. Ushbu yondashuv muvaffaqiyatli bo'lishi uchun to'qimalarni mikro miqyosda takrorlash kerak. Shuning uchun mikro muhitni, bu mikromuhitdagi biologik kuchlarning tabiatini, funktsional va yordamchi hujayra turlarining aniq tashkil etilishini, eruvchanlik omillarini va hujayradan tashqari matritsaning tarkibini tushunish kerak. |

|||

===Avtonom o'z-o'zini yig'ish=== |

|||

* [http://vademec.ru/news/detail54638.html Rossiyalik olimlar 3D printerda qalqonsimon bezni chop etishdi] |

|||

Bioprintingning ikkinchi yondashuvi - avtonom o'zini o'zi yig'ish. Bu yondashuv embrion organ rivojlanishining fizik jarayoniga tayanadi. Hujayralar erta rivojlanish bosqichida bo'lganida, ular o'zlarining hujayradan tashqari matritsa qurilish bloklarini, tegishli hujayra signalizatsiyasini va kerakli biologik funktsiyalar va mikro-arxitekturani ta'minlash uchun mustaqil tartibga solish va naqshlarni yaratadilar.[13] Avtonom o'z-o'zini yig'ish embrionning to'qimalari va organlarining rivojlanish texnikasi haqida aniq ma'lumotni talab qiladi.[14] "Iskalasiz" model mavjud bo'lib, u o'z-o'zidan yig'iladigan sferoidlardan foydalanadi, ular termoyadroviyga va hujayra tuzilishiga, rivojlanayotgan to'qimalarga o'xshaydi. Avtonom o'z-o'zini yig'ish hujayraga gistogenezning asosiy drayveri sifatida bog'liq bo'lib, bu to'qimalarning qurilish bloklarini, strukturaviy va funktsional xususiyatlarini boshqaradi. Bu embrion to'qimalarining mexanizmlari qanday rivojlanishini, shuningdek bioprinted to'qimalarni yaratish uchun o'rab olingan mikro muhitni chuqurroq tushunishni talab qiladi.[13] |

|||

* [http://rusplt.ru/society/v-rossii-nachali-pechatat-organyi-16170.html Rossiyada organlar chop etila boshlandi] |

|||

* Video: [https://www.youtube.com/watch?t=47&v=a7_JCIfX-yg tiroid], [https://www.youtube.com/watch?v=VNADmZuBSTU 3D texnologiyalari dunyoni faol ravishda qamrab] oladi - |

|||

* Yoo, S. S. (2015). [http://informahealthcare.com/doi/abs/10.1517/13543776.2015.1019466 3D-printed biological organs: medical potential and patenting opportunity]. Expert opinion on therapeutic patents, (0), 1-5. |

|||

== |

===Mini-tissue=== |

||

The third approach of bioprinting is a combination of both the biomimicry and self-assembly approaches, which is called mini tissues. Organs and tissues are built from very small functional components. Mini-tissue approach takes these small pieces and manufacture and arrange them into larger framework.<ref name=Yoo/><ref name=Murphy/> |

|||

== Printers == |

|||

* [http://www.journals.elsevier.com/bioprinting Bioprinting journal]. |

|||

[[File:Printer 3D Bioprinting Solutions.jpg|thumb|right|A 3D bioprinter]] |

|||

Akin to ordinary ink printers, bioprinters have three major components to them. These are the hardware used, the type of bio-ink, and the material it is printed on (biomaterials).<ref name=":02" /> |

|||

"Bio-ink is a material made from living cells that behaves much like a liquid, allowing people to 'print' it in order to create the desired shape. To make bio-ink, scientists create a slurry of cells that can be loaded into a cartridge and inserted into a specially designed printer, along with another cartridge containing a gel known as bio-paper."<ref>{{cite book | url=https://books.google.com/books?id=7cAqCwAAQBAJ&pg=PA417 | title=Basic Dental Materials | publisher=JP Medical Ltd | vauthors = Manappallil JJ | year=2015 | isbn=9789352500482}}</ref> |

|||

In bioprinting, there are three major types of printers that have been used. These are inkjet, laser-assisted, and extrusion printers. Inkjet printers are mainly used in bioprinting for fast and large-scale products. One type of inkjet printer, called drop-on-demand inkjet printer, prints materials in exact amounts, minimizing cost and waste.<ref>{{cite news|title=3D Printing Technology At The Service Of Health|url=http://www.healthyeve.com/3d-printing-technology-service-health/|access-date=4 August 2016|work=healthyeve|archive-date=14 September 2016|archive-url=https://web.archive.org/web/20160914161301/http://www.healthyeve.com/3d-printing-technology-service-health/|url-status=dead}}</ref> Printers that utilize lasers provide high-resolution printing; however, these printers are often expensive. Extrusion printers print cells layer-by-layer, just like [[3D printing]] to create 3D constructs. In addition to just cells, extrusion printers may also use hydrogels infused with cells.<ref name=":02" /> |

|||

=== Extrusion-Based Methods === |

|||

[[Turkum:Tibbiyot]] |

|||

Extrusion-based printing is a very common technique within the field of 3D printing which entails extruding, or forcing, a continuous stream of melted solid material or viscous liquid through a sort of orifice, often a nozzle or syringe.<ref name=":0">{{Cite journal|vauthors=Lepowsky E, Muradoglu M, Tasoglu S|date=2018|title=Towards preserving post-printing cell viability and improving the resolution: Past, present, and future of 3D bioprinting theory|url=http://home.ku.edu.tr/~mmuradoglu/LepowskyEtAlBioprinting2018.pdf|journal=Bioprinting|volume=11|pages=e00034|doi=10.1016/j.bprint.2018.e00034|s2cid=69929012 |issn=2405-8866|via=Elsevier Science Direct}}</ref> When it comes to extrusion based bioprinting, there are three main type of extrusion. These are pneumatic driven, piston driven, and screw driven. Each extrusion method has their own advantages and disadvantages. Pneumatic extrusion uses pressurized air to force liquid bioink through a depositing agent. The air used to move the bioink must be free of contaminants. Air filters are commonly used to sterilize the air before it is used.<ref>{{cite journal|vauthors=Gu Z, Fu J, Lin H, He Y|date=September 2020|title=Development of 3D bioprinting: From printing methods to biomedical applications|journal=Asian Journal of Pharmaceutical Sciences|volume=15|issue=5|pages=529–557|doi=10.1016/j.ajps.2019.11.003|pmc=7610207|pmid=33193859}}</ref> Piston driven extrusion utilizes a piston connected to a guide screw. The linear motion of the piston squeezes material out of the nozzle. Screw driven extrusion uses an auger screw to extrude material. The rotational motion forces the material down and out of the nozzle.<ref>{{cite journal|vauthors=Derakhshanfar S, Mbeleck R, Xu K, Zhang X, Zhong W, Xing M|date=June 2018|title=3D bioprinting for biomedical devices and tissue engineering: A review of recent trends and advances|journal=Bioactive Materials|volume=3|issue=2|pages=144–156|doi=10.1016/j.bioactmat.2017.11.008|pmc=5935777|pmid=29744452|doi-access=free}}</ref> Screw driven devices allow for the use of higher viscosity materials and provide more volumetric control.<ref name=":0" /> Once printed, many materials require a crosslinking step to achieve the desired mechanical properties for the construct, which can be achieved for example with the treatment of chemical agents or photo-crosslinkers. |

|||

[[Turkum:Biotexnologiya]] |

|||

Direct extrusion is one of the most common extrusion-based bioprinting techniques, wherein the pressurized force directs the bioink to flow out of the nozzle, and directly print the scaffold without any necessary casting.<ref name=":2">{{Cite journal|last1=Datta|first1=Pallab|last2=Ayan|first2=Bugra|last3=Ozbolat|first3=Ibrahim T.|date=March 2017|title=Bioprinting for vascular and vascularized tissue biofabrication|url=http://dx.doi.org/10.1016/j.actbio.2017.01.035|journal=Acta Biomaterialia|volume=51|pages=1–20|doi=10.1016/j.actbio.2017.01.035|pmid=28087487 |issn=1742-7061}}</ref> The bioink itself for this approach can be a blend of polymer hydrogels, naturally derived materials such as [[collagen]], and live cells suspended in the solution.<ref name=":2" /> In this manner, scaffolds can be cultured post-print and without the need further treatment for cellular seeding. Some focus in the use of direct printing techniques is based upon the use of coaxial nozzle assemblies, or coaxial extrusion. The coaxial nozzle setup enables the simultaneous extrusion of multiple material bioinks, capable of making multi-layered scaffolds in a single extrusion step.<ref name=":3">{{Cite journal|last1=Gupta|first1=Prerak|last2=Mandal|first2=Biman B.|date=2021-06-12|title=Tissue‐Engineered Vascular Grafts: Emerging Trends and Technologies|url=http://dx.doi.org/10.1002/adfm.202100027|journal=Advanced Functional Materials|volume=31|issue=33|pages=2100027|doi=10.1002/adfm.202100027|s2cid=236235572 |issn=1616-301X}}</ref> The development of tubular structures has found the layered extrusion achieved via these techniques desirable for the radial variability in material characterization that it can offer, as the coaxial nozzle provides an inner and outer tube for bioink flow.<ref name=":3" /> Indirect extrusion techniques for bioprinting rather require the printing of a base material of cell-laden hydrogels, but unlike direct extrusion contains a sacrificial hydrogel that can be trivially removed post-printing through thermal or chemical extraction.<ref>{{Cite journal|last1=Hinton|first1=Thomas J.|last2=Jallerat|first2=Quentin|last3=Palchesko|first3=Rachelle N.|last4=Park|first4=Joon Hyung|last5=Grodzicki|first5=Martin S.|last6=Shue|first6=Hao-Jan|last7=Ramadan|first7=Mohamed H.|last8=Hudson|first8=Andrew R.|last9=Feinberg|first9=Adam W.|date=2015-10-30|title=Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels|journal=Science Advances|language=en|volume=1|issue=9|pages=e1500758|doi=10.1126/sciadv.1500758|issn=2375-2548|pmc=4646826|pmid=26601312|bibcode=2015SciA....1E0758H }}</ref> The remaining resin solidifies and becomes the desired 3D-printed construct. |

|||

=== Other Printing Methods === |

|||

Droplet-based bioprinting is a technique in which the bioink blend of cells and/or hydrogels are placed in droplets in precise positions. Most common amongst this approach are thermal and piezoelectric-drop-on-demand techniques.<ref>{{Cite journal|last1=Munaz|first1=Ahmed|last2=Vadivelu|first2=Raja K.|last3=St. John|first3=James|last4=Barton|first4=Matthew|last5=Kamble|first5=Harshad|last6=Nguyen|first6=Nam-Trung|date=March 2016|title=Three-dimensional printing of biological matters|url=http://dx.doi.org/10.1016/j.jsamd.2016.04.001|journal=Journal of Science: Advanced Materials and Devices|volume=1|issue=1|pages=1–17|doi=10.1016/j.jsamd.2016.04.001|issn=2468-2179}}</ref> Thermal technologies use short duration signals to heat the bioink, inducing the formation of small bubbles which are ejected. Piezoelectric bioprinting has short duration current rather applied to a [[piezoelectric actuator]], which induces mechanical a vibration capable of ejecting a small globule of bioink through the nozzle. A significant aspect of the study of droplet-based approaches to bioprinting is accounting for mechanical and thermal stress cells within the bioink experience near the nozzle-tip as they are extruded. |

|||

Laser-based bioprinting can be distinguished between two major classes in general, those being based upon either cell transfer technologies or [[Photo polymerization|photo-polymerization]]. In cell transfer laser printing, a laser stimulates the interface between energy-absorbing material (e.g. gold, titanium, etc.) and the bioink, which contains a sacrificial material. This sacrificial ‘donor layer’ vaporizes under the laser’s irradiation, forming a bubble from the bioink layer which gets deposited from a jet.<ref>{{Citation|last1=Devillard|first1=Raphaël|title=Cell Patterning by Laser-Assisted Bioprinting|date=2014|url=https://linkinghub.elsevier.com/retrieve/pii/B9780124167421000093|journal=Methods in Cell Biology|volume=119|pages=159–174|publisher=Elsevier|language=en|doi=10.1016/b978-0-12-416742-1.00009-3|isbn=978-0-12-416742-1|access-date=2021-10-27|last2=Pagès|first2=Emeline|last3=Correa|first3=Manuela Medina|last4=Kériquel|first4=Virginie|last5=Rémy|first5=Murielle|last6=Kalisky|first6=Jérôme|last7=Ali|first7=Muhammad|last8=Guillotin|first8=Bertrand|last9=Guillemot|first9=Fabien|pmid=24439284 }}</ref> Photo-polymerization techniques rather use photoinitiated reactions to solidify the ink, moving the beam path of a laser to induce the formation of a desired construct. Certain laser frequencies paired with photopolymerization reactions can be carried out without damaging cells laden into the material. |

|||

{| class="wikitable" |

|||

|+Types of Bioprinters |

|||

!Method of Bioprinting |

|||

!Mode of Printing |

|||

!Advantages |

|||

|- |

|||

|Direct printing |

|||

|Extrusion-based |

|||

|Simple execution, no casting |

|||

|- |

|||

|Coaxial extrusion |

|||

|Extrusion-based |

|||

|Single step formation of multi-layered constructs |

|||

|- |

|||

|Indirect |

|||

|Extrusion-based |

|||

|Requires a removeable 'sacrificial material' to support structural formation |

|||

|- |

|||

|Laser |

|||

|Laser-based |

|||

|No shear stress upon cells suspended in ink |

|||

|- |

|||

|Droplet |

|||

|Droplet-based |

|||

|Precise control over flow & formation of scaffold |

|||

|} |

|||

== Applications == |

|||

===Transplantable organs and organs for research=== |

|||

There are several applications for 3D bioprinting in the medical field. An infant patient with a rare respiratory disease known as [[tracheobronchomalacia]] (TBM) was given a tracheal splint that was created with 3D printing.<ref>{{cite journal | vauthors = Zopf DA, Hollister SJ, Nelson ME, Ohye RG, Green GE | title = Bioresorbable airway splint created with a three-dimensional printer | journal = The New England Journal of Medicine | volume = 368 | issue = 21 | pages = 2043–5 | date = May 2013 | pmid = 23697530 | doi = 10.1056/NEJMc1206319 }}</ref> 3D bioprinting can be used to reconstruct tissue from various regions of the body. Patients with end-stage bladder disease can be treated by using engineered bladder tissues to rebuild the damaged organ.<ref>{{cite journal | vauthors = Atala A, Bauer SB, Soker S, Yoo JJ, Retik AB | title = Tissue-engineered autologous bladders for patients needing cystoplasty | journal = Lancet | volume = 367 | issue = 9518 | pages = 1241–6 | date = April 2006 | pmid = 16631879 | doi = 10.1016/S0140-6736(06)68438-9 | s2cid = 17892321 }}</ref> This technology can also potentially be applied to bone, skin, cartilage and muscle tissue.<ref>{{cite journal | vauthors = Hong N, Yang GH, Lee J, Kim G | title = 3D bioprinting and its in vivo applications | journal = Journal of Biomedical Materials Research Part B: Applied Biomaterials | volume = 106 | issue = 1 | pages = 444–459 | date = January 2018 | pmid = 28106947 | doi = 10.1002/jbm.b.33826 }}</ref> Though one long-term goal of 3D bioprinting technology is to reconstruct an entire organ, there has been little success in printing fully functional organs.<ref>{{cite journal | vauthors = Sommer AC, Blumenthal EZ | title = Implementations of 3D printing in ophthalmology | journal = Graefe's Archive for Clinical and Experimental Ophthalmology| volume = 257 | issue = 9 | pages = 1815–1822 | date = September 2019 | pmid = 30993457 | doi = 10.1007/s00417-019-04312-3 | s2cid = 116884575 }}</ref> Unlike implantable stents, organs have complex shapes and are significantly harder to bioprint. A bioprinted heart, for example, must not only meet structural requirements, but also vascularization, mechanical load, and electrical signal propagation requirements.<ref name="CuiMiao2018">{{cite journal | vauthors = Cui H, Miao S, Esworthy T, Zhou X, Lee SJ, Liu C, Yu ZX, Fisher JP, Mohiuddin M, Zhang LG | display-authors = 6 | title = 3D bioprinting for cardiovascular regeneration and pharmacology | journal = Advanced Drug Delivery Reviews | volume = 132 | pages = 252–269 | date = July 2018 | pmid = 30053441 | pmc = 6226324 | doi = 10.1016/j.addr.2018.07.014 }}</ref> Israeli researchers constructed a rabbit-sized heart out of human cells in 2019.<ref>{{Cite web|url=https://www.nbcnews.com/mach/science/israeli-scientists-create-world-s-first-3d-printed-heart-using-ncna996031|title=Israeli scientists create world's first 3D-printed heart using human cells|work=NBC News |date=April 19, 2019 | vauthors = Freeman D |access-date=2019-04-20}}</ref> |

|||

In 2022, first success of a clinical trial for a 3D bioprinted transplant that is made from the patient's own cells, an [[Auricle (anatomy)|external ear]] to treat [[microtia]],<ref>{{cite web |title=A Multicenter, Single Arm, Prospective, Open-Label, Staged Study of the Safety and Efficacy of the AuriNovo Construct for Auricular Reconstruction in Subjects With Unilateral Microtia |url=https://clinicaltrials.gov/ct2/show/NCT04399239 |publisher=clinicaltrials.gov |access-date=19 July 2022 |date=15 October 2021}}</ref> was reported.<ref>{{cite web |last1=Rabin |first1=Roni Caryn |title=Doctors Transplant Ear of Human Cells, Made by 3-D Printer |url=https://www.nytimes.com/2022/06/02/health/ear-transplant-3d-printer.html |website=The New York Times |access-date=19 July 2022 |date=2 June 2022}}</ref> |

|||

===Cultured meat=== |

|||

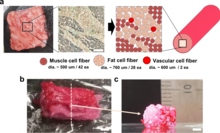

[[File:Assembly of fibrous muscle, fat, and vascular tissues to cultured steak.webp|thumb|Such steak-like meat could mitigate issues of [[environmental impact of meat production]] and [[animal welfare]].]] |

|||

Bioprinting can also be used for [[cultured meat]]. In 2021, a steak-like cultured meat, composed of three types of bovine cell fibers was produced. The [[Wagyu]]-like beef has a structure similar to original meat.<ref>{{cite news |title=Japanese scientists produce first 3D-bioprinted, marbled Wagyu beef |url=https://newatlas.com/science/world-first-lab-grown-wagyu-beef-japan/ |access-date=21 September 2021 |work=New Atlas |date=25 August 2021}}</ref><ref>{{cite journal | vauthors = Kang DH, Louis F, Liu H, Shimoda H, Nishiyama Y, Nozawa H, Kakitani M, Takagi D, Kasa D, Nagamori E, Irie S, Kitano S, Matsusaki M | display-authors = 6 | title = Engineered whole cut meat-like tissue by the assembly of cell fibers using tendon-gel integrated bioprinting | journal = Nature Communications | volume = 12 | issue = 1 | pages = 5059 | date = August 2021 | pmid = 34429413 | doi = 10.1038/s41467-021-25236-9 | pmc = 8385070 | bibcode = 2021NatCo..12.5059K }}</ref> |

|||

==Impact== |

|||

3D bioprinting contributes to significant advances in the medical field of [[tissue engineering]] by allowing for research to be done on innovative materials called [[biomaterials]]. Biomaterials are the materials adapted and used for printing three-dimensional objects. Some of the most notable bioengineered substances are usually stronger than the average bodily materials, including soft tissue and bone. These constituents can act as future substitutes, even improvements, for the original body materials. [[Alginate]], for example, is an anionic polymer with many biomedical implications including feasibility, strong biocompatibility, low toxicity, and stronger structural ability in comparison to some of the body's structural material.<ref name="asme">{{cite web |url=https://www.asme.org/engineering-topics/articles/bioengineering/creating-valve-tissue-using-3d-bioprinting |title=Creating Valve Tissue Using 3-D Bioprinting | vauthors = Crawford M |work=ASME.org |publisher=American Society of Mechanical Engineers |date=May 2013 |access-date=17 February 2016}}</ref> Synthetic hydrogels are also commonplace, including PV-based gels. The combination of acid with a UV-initiated PV-based cross-linker has been evaluated by the Wake Forest Institute of Medicine and determined to be a suitable biomaterial.<ref name="MurphyEval12">{{cite journal | vauthors = Murphy SV, Skardal A, Atala A | title = Evaluation of hydrogels for bio-printing applications | journal = Journal of Biomedical Materials Research. Part A | volume = 101 | issue = 1 | pages = 272–84 | date = January 2013 | pmid = 22941807 | doi = 10.1002/jbm.a.34326 }}</ref> Engineers are also exploring other options such as printing micro-channels that can maximize the diffusion of nutrients and oxygen from neighboring tissues.<ref name="cooper" /> In addition, the [[Defense Threat Reduction Agency]] aims to print mini organs such as hearts, livers, and lungs as the potential to test new drugs more accurately and perhaps eliminate the need for testing in animals.<ref name="cooper" /> |

|||

== See also == |

|||

{{wiktionary|bioprinting}} |

|||

* [[3D printing#Bio-printing|3D printing § Bio-printing]] |

|||

* [[Cultured meat]] |

|||

* [[Ethics of bioprinting]] |

|||

* [[Magnetic 3D bioprinting]] |

|||

* [[Regenerative medicine]] |

|||

== References == |

|||

{{reflist}} |

|||

== Further reading == |

|||

{{refbegin}} |

|||

* {{cite journal | vauthors = Tran J |year=2015 |title=To Bioprint or Not to Bioprint |journal=North Carolina Journal of Law and Technology |volume=17 |pages=123–78 |ssrn=2562952 |url=http://ncjolt.org/to-bioprint-or-not-to-bioprint-2/ |access-date=2019-01-12 |archive-date=2019-03-10 |archive-url=https://web.archive.org/web/20190310091342/http://ncjolt.org/to-bioprint-or-not-to-bioprint-2/ |url-status=dead }} |

|||

* {{cite journal | vauthors = Tran J |date=May 7, 2015 |title=Patenting Bioprinting |journal=Harvard Journal of Law and Technology Digest |volume=29 |ssrn=2603693}} |

|||

* {{cite book| vauthors = Vishwakarma A |title=Stem Cell Biology and Tissue Engineering in Dental Sciences |publisher= Elsevier, 2014 |isbn=9780123971579|url=https://books.google.com/books?id=22ipoAEACAAJ|date=2014-11-27}} |

|||

{{refend}} |

|||

{{Health care}} |

|||

<!---Place all category tags here--> |

|||

[[Category:3D printing|Bioprinting]] |

|||

[[Category:Biomaterials]] |

|||

[[Category:Tissue engineering]] |

|||

[[Category:Synthetic biology]] |

|||

[[Category:Self-replication]] |

|||

13-Sentyabr 2022, 19:13 dagi koʻrinishi

Uch o'lchovli (3D) bioprinting - ko'pincha tabiiy to'qimalarning xususiyatlarini taqlid qilish maqsadida biotibbiy qismlarni ishlab chiqarish uchun hujayralarni, o'sish omillarini va/yoki biomateriallarni birlashtirish uchun 3D bosib chiqarishga o'xshash usullardan foydalanish. Umuman olganda, 3D bioprinting bio-siyoh deb nomlanuvchi materiallarni to‘ldirish uchun qatlam-qatlam usulidan foydalanib, keyinchalik turli tibbiyot va to‘qima muhandisligi sohalarida qo‘llaniladigan to‘qimalarga o‘xshash tuzilmalarni yaratishi mumkin. 3D bioprinting bioprinting texnikasi va biomateriallarning keng doirasini qamrab oladi. Hozirda bioprinting yordamida dori va potentsial muolajalarni tadqiq qilishda to‘qima va organ modellarini chop etish mumkin. Shunga qaramay, bioprinted tirik hujayra konstruksiyalarini klinik qo'llashga tarjima qilish funktsional organlarni yaratish uchun zarur bo'lgan murakkablik va hujayralar soni tufayli bir qancha muammolarga duch keladi. Biroq, innovatsiyalar hujayradan tashqari matritsaning bioprintsiyasidan tortib, kerakli to'qimalarni hosil qilish uchun qatlam bo'ylab yotqizilgan gidrogellar bilan hujayralarni aralashtirishgacha davom etadi. Bundan tashqari, 3D bioprinting iskalalarni bosib chiqarishni o'z ichiga boshladi. Bu iskalalardan bo'g'inlar va ligamentlarni qayta tiklash uchun foydalanish mumkin.[1]

Jarayon

33D bioprinting odatda uchta bosqichdan iborat: bioprintingdan oldingi, bioprinting va post-bioprinting.[7][8][2][3]

Bioprintingga tayyorgarlik

Oldindan bioprinting bu printer keyinchalik yaratadigan modelni yaratish va foydalaniladigan materiallarni tanlash jarayonidir. Birinchi qadamlardan biri organning biopsiyasini olishdir. Bioprinting uchun ishlatiladigan umumiy texnologiyalar kompyuter tomografiyasi (KT) va magnit-rezonans tomografiya (MRI). Qatlam-qatlam yondashuvi bilan chop etish uchun tasvirlarda tomografik rekonstruksiya amalga oshiriladi. Endi 2D tasvirlar keyinchalik tayyorlanish uchun printerga yuboriladi. Tasvir yaratilgandan so'ng, ma'lum hujayralar ajratiladi va ko'paytiriladi.[7] Keyin bu hujayralar kislorod va boshqa oziq moddalar bilan ta'minlaydigan maxsus suyultirilgan material bilan aralashtiriladi. Ba'zi jarayonlarda hujayralar diametri 500 mkm bo'lgan hujayrali sferoidlar bilan qoplangan. Hujayralarning bunday yig'indisi iskala talab qilmaydi va ekstruziya kabi jarayonlar uchun quvur shaklidagi to'qimalarning sinteziga joylashtirish uchun talab qilinadi.[9]: 165 [4]:165

Bioprintlash

Ikkinchi bosqichda bioinks deb nomlanuvchi hujayralar, matritsalar va ozuqa moddalarining suyuq aralashmasi printer kartrijiga joylashtiriladi va bemorlarning tibbiy skanerlari yordamida biriktiriladi.[10] Bioprinted oldingi to'qima inkubatorga o'tkazilganda, bu hujayraga asoslangan oldingi to'qima to'qimaga aylanadi.

Biologik konstruksiyalarni ishlab chiqarish uchun 3D bioprinting odatda to‘qimalarga o‘xshash uch o‘lchamli tuzilmalarni yaratish uchun ketma-ket qatlam-qatlam yondashuvidan foydalangan holda hujayralarni biomos keluvchi iskala ustiga tarqatishni o‘z ichiga oladi.[11] 3D bioprinting yordamida yaratilgan jigar va buyraklar kabi sunʼiy organlarda qon tomirlari, siydik toʻplash uchun naychalar va bu organlar uchun zarur boʻlgan milliardlab hujayralar oʻsishi kabi tanaga taʼsir qiluvchi muhim elementlar yoʻqligi koʻrsatilgan. Ushbu komponentlarsiz tananing asosiy oziq moddalari va kislorodni ichki qismiga chuqurroq olish imkoni yo'q.[11] Tanadagi har bir to'qima tabiiy ravishda turli xil hujayra turlaridan iborat ekanligini hisobga olsak, bu hujayralarni bosib chiqarish uchun ko'plab texnologiyalar ishlab chiqarish jarayonida hujayralarning barqarorligi va hayotiyligini ta'minlash qobiliyatiga qarab farqlanadi. Hujayralarni 3D bioprinting uchun ishlatiladigan ba'zi usullar fotolitografiya, magnitli 3D bioprinting, stereolitografiya va to'g'ridan-to'g'ri hujayra ekstruziyasi.[9]: 196.[5] Artificial organs such as livers and kidneys made by 3D bioprinting have been shown to lack crucial elements that affect the body such as working blood vessels, tubules for collecting urine, and the growth of billions of cells required for these organs. Without these components the body has no way to get the essential nutrients and oxygen deep within their interiors.[5] Given that every tissue in the body is naturally composed of different cell types, many technologies for printing these cells vary in their ability to ensure stability and viability of the cells during the manufacturing process. Some of the methods that are used for 3D bioprinting of cells are photolithography, magnetic 3D bioprinting, stereolithography, and direct cell extrusion.[4]:196

Bioprintlashdan keyin

Ikkinchi bosqichda bioinks deb nomlanuvchi hujayralar, matritsalar va ozuqa moddalarining suyuq aralashmasi printer kartrijiga joylashtiriladi va bemorlarning tibbiy skanerlari yordamida biriktiriladi.[10] Bioprinted oldingi to'qima inkubatorga o'tkazilganda, bu hujayraga asoslangan oldingi to'qima to'qimaga aylanadi.

Biologik konstruksiyalarni ishlab chiqarish uchun 3D bioprinting odatda to‘qimalarga o‘xshash uch o‘lchamli tuzilmalarni yaratish uchun ketma-ket qatlam-qatlam yondashuvidan foydalangan holda hujayralarni biomos keluvchi iskala ustiga tarqatishni o‘z ichiga oladi.[11] 3D bioprinting yordamida yaratilgan jigar va buyraklar kabi sunʼiy organlarda qon tomirlari, siydik toʻplash uchun naychalar va bu organlar uchun zarur boʻlgan milliardlab hujayralar oʻsishi kabi tanaga taʼsir qiluvchi muhim elementlar yoʻqligi koʻrsatilgan. Ushbu komponentlarsiz tananing asosiy oziq moddalari va kislorodni ichki qismiga chuqurroq olish imkoni yo'q.[11] Tanadagi har bir to'qima tabiiy ravishda turli xil hujayra turlaridan iborat ekanligini hisobga olsak, bu hujayralarni bosib chiqarishning ko'plab texnologiyalari biologik materialdan barqaror strukturani yaratish uchun bioprintingdan keyingi jarayon davomida hujayralarning barqarorligi va hayotiyligini ta'minlash qobiliyatiga ko'ra farqlanadi. . Agar bu jarayon yaxshi saqlanmasa, 3D bosilgan ob'ektning mexanik yaxlitligi va funksiyasi xavf ostida.[7] Ob'ektni ushlab turish uchun ham mexanik, ham kimyoviy stimulyatsiya kerak. Ushbu stimulyatsiyalar to'qimalarning qayta tuzilishi va o'sishini nazorat qilish uchun hujayralarga signallarni yuboradi. Bundan tashqari, so'nggi ishlanmalarda bioreaktor texnologiyalari[12] to'qimalarning tez pishishiga, to'qimalarning tomirlanishiga va transplantatsiyadan omon qolish qobiliyatiga imkon berdi.[8]

Bioreaktorlar ozuqa moddalarini konvektiv tashishda, mikrogravitatsiya muhitini yaratishda, eritmaning hujayralar bo'ylab oqib ketishiga olib keladigan bosimni o'zgartirishda yoki dinamik yoki statik yuklash uchun siqishni qo'shishda ishlaydi. Har bir turdagi bioreaktorlar har xil turdagi to'qimalar uchun idealdir, masalan, siqish bioreaktorlari xaftaga to'qimalari uchun idealdir.[9]: 198 he ishlab chiqarish jarayoni. Hujayralarni 3D bioprinting uchun ishlatiladigan ba'zi usullar fotolitografiya, magnitli 3D bioprinting, stereolitografiya va to'g'ridan-to'g'ri hujayra ekstruziyasi.[9]: 196.[4]:198

Bioprintlash yondashuvi

Ushbu sohadagi tadqiqotchilar tegishli biologik va mexanik xususiyatlarga ega bo'lgan tirik organlarni ishlab chiqarish uchun yondashuvlarni ishlab chiqdilar. 3D bioprinting uchta asosiy yondashuvga asoslanadi: biomimikriya, avtonom o'z-o'zini yig'ish va mini-to'qimalarni qurish bloklari.[13][6]

Biomimikriya

Bioprintingning birinchi yondashuvi biomimikriya deb ataladi. Ushbu yondashuvning asosiy maqsadi inson tanasidagi to'qimalar va organlarda mavjud bo'lgan tabiiy tuzilishga o'xshash uydirma tuzilmalarni yaratishdir. Biomimikriya organlar va to'qimalarning shakli, ramkasi va mikro muhitini takrorlashni talab qiladi.[14] Bioprintingda biomimikriyani qo'llash organlarning bir xil hujayrali va hujayradan tashqari qismlarini yaratishni o'z ichiga oladi. Ushbu yondashuv muvaffaqiyatli bo'lishi uchun to'qimalarni mikro miqyosda takrorlash kerak. Shuning uchun mikro muhitni, bu mikromuhitdagi biologik kuchlarning tabiatini, funktsional va yordamchi hujayra turlarining aniq tashkil etilishini, eruvchanlik omillarini va hujayradan tashqari matritsaning tarkibini tushunish kerak.

Avtonom o'z-o'zini yig'ish

Bioprintingning ikkinchi yondashuvi - avtonom o'zini o'zi yig'ish. Bu yondashuv embrion organ rivojlanishining fizik jarayoniga tayanadi. Hujayralar erta rivojlanish bosqichida bo'lganida, ular o'zlarining hujayradan tashqari matritsa qurilish bloklarini, tegishli hujayra signalizatsiyasini va kerakli biologik funktsiyalar va mikro-arxitekturani ta'minlash uchun mustaqil tartibga solish va naqshlarni yaratadilar.[13] Avtonom o'z-o'zini yig'ish embrionning to'qimalari va organlarining rivojlanish texnikasi haqida aniq ma'lumotni talab qiladi.[14] "Iskalasiz" model mavjud bo'lib, u o'z-o'zidan yig'iladigan sferoidlardan foydalanadi, ular termoyadroviyga va hujayra tuzilishiga, rivojlanayotgan to'qimalarga o'xshaydi. Avtonom o'z-o'zini yig'ish hujayraga gistogenezning asosiy drayveri sifatida bog'liq bo'lib, bu to'qimalarning qurilish bloklarini, strukturaviy va funktsional xususiyatlarini boshqaradi. Bu embrion to'qimalarining mexanizmlari qanday rivojlanishini, shuningdek bioprinted to'qimalarni yaratish uchun o'rab olingan mikro muhitni chuqurroq tushunishni talab qiladi.[13]

Mini-tissue

The third approach of bioprinting is a combination of both the biomimicry and self-assembly approaches, which is called mini tissues. Organs and tissues are built from very small functional components. Mini-tissue approach takes these small pieces and manufacture and arrange them into larger framework.[7][6]

Printers

Akin to ordinary ink printers, bioprinters have three major components to them. These are the hardware used, the type of bio-ink, and the material it is printed on (biomaterials).[2] "Bio-ink is a material made from living cells that behaves much like a liquid, allowing people to 'print' it in order to create the desired shape. To make bio-ink, scientists create a slurry of cells that can be loaded into a cartridge and inserted into a specially designed printer, along with another cartridge containing a gel known as bio-paper."[8] In bioprinting, there are three major types of printers that have been used. These are inkjet, laser-assisted, and extrusion printers. Inkjet printers are mainly used in bioprinting for fast and large-scale products. One type of inkjet printer, called drop-on-demand inkjet printer, prints materials in exact amounts, minimizing cost and waste.[9] Printers that utilize lasers provide high-resolution printing; however, these printers are often expensive. Extrusion printers print cells layer-by-layer, just like 3D printing to create 3D constructs. In addition to just cells, extrusion printers may also use hydrogels infused with cells.[2]

Extrusion-Based Methods

Extrusion-based printing is a very common technique within the field of 3D printing which entails extruding, or forcing, a continuous stream of melted solid material or viscous liquid through a sort of orifice, often a nozzle or syringe.[10] When it comes to extrusion based bioprinting, there are three main type of extrusion. These are pneumatic driven, piston driven, and screw driven. Each extrusion method has their own advantages and disadvantages. Pneumatic extrusion uses pressurized air to force liquid bioink through a depositing agent. The air used to move the bioink must be free of contaminants. Air filters are commonly used to sterilize the air before it is used.[11] Piston driven extrusion utilizes a piston connected to a guide screw. The linear motion of the piston squeezes material out of the nozzle. Screw driven extrusion uses an auger screw to extrude material. The rotational motion forces the material down and out of the nozzle.[12] Screw driven devices allow for the use of higher viscosity materials and provide more volumetric control.[10] Once printed, many materials require a crosslinking step to achieve the desired mechanical properties for the construct, which can be achieved for example with the treatment of chemical agents or photo-crosslinkers.

Direct extrusion is one of the most common extrusion-based bioprinting techniques, wherein the pressurized force directs the bioink to flow out of the nozzle, and directly print the scaffold without any necessary casting.[13] The bioink itself for this approach can be a blend of polymer hydrogels, naturally derived materials such as collagen, and live cells suspended in the solution.[13] In this manner, scaffolds can be cultured post-print and without the need further treatment for cellular seeding. Some focus in the use of direct printing techniques is based upon the use of coaxial nozzle assemblies, or coaxial extrusion. The coaxial nozzle setup enables the simultaneous extrusion of multiple material bioinks, capable of making multi-layered scaffolds in a single extrusion step.[14] The development of tubular structures has found the layered extrusion achieved via these techniques desirable for the radial variability in material characterization that it can offer, as the coaxial nozzle provides an inner and outer tube for bioink flow.[14] Indirect extrusion techniques for bioprinting rather require the printing of a base material of cell-laden hydrogels, but unlike direct extrusion contains a sacrificial hydrogel that can be trivially removed post-printing through thermal or chemical extraction.[15] The remaining resin solidifies and becomes the desired 3D-printed construct.

Other Printing Methods

Droplet-based bioprinting is a technique in which the bioink blend of cells and/or hydrogels are placed in droplets in precise positions. Most common amongst this approach are thermal and piezoelectric-drop-on-demand techniques.[16] Thermal technologies use short duration signals to heat the bioink, inducing the formation of small bubbles which are ejected. Piezoelectric bioprinting has short duration current rather applied to a piezoelectric actuator, which induces mechanical a vibration capable of ejecting a small globule of bioink through the nozzle. A significant aspect of the study of droplet-based approaches to bioprinting is accounting for mechanical and thermal stress cells within the bioink experience near the nozzle-tip as they are extruded.

Laser-based bioprinting can be distinguished between two major classes in general, those being based upon either cell transfer technologies or photo-polymerization. In cell transfer laser printing, a laser stimulates the interface between energy-absorbing material (e.g. gold, titanium, etc.) and the bioink, which contains a sacrificial material. This sacrificial ‘donor layer’ vaporizes under the laser’s irradiation, forming a bubble from the bioink layer which gets deposited from a jet.[17] Photo-polymerization techniques rather use photoinitiated reactions to solidify the ink, moving the beam path of a laser to induce the formation of a desired construct. Certain laser frequencies paired with photopolymerization reactions can be carried out without damaging cells laden into the material.

| Method of Bioprinting | Mode of Printing | Advantages |

|---|---|---|

| Direct printing | Extrusion-based | Simple execution, no casting |

| Coaxial extrusion | Extrusion-based | Single step formation of multi-layered constructs |

| Indirect | Extrusion-based | Requires a removeable 'sacrificial material' to support structural formation |

| Laser | Laser-based | No shear stress upon cells suspended in ink |

| Droplet | Droplet-based | Precise control over flow & formation of scaffold |

Applications

Transplantable organs and organs for research

There are several applications for 3D bioprinting in the medical field. An infant patient with a rare respiratory disease known as tracheobronchomalacia (TBM) was given a tracheal splint that was created with 3D printing.[18] 3D bioprinting can be used to reconstruct tissue from various regions of the body. Patients with end-stage bladder disease can be treated by using engineered bladder tissues to rebuild the damaged organ.[19] This technology can also potentially be applied to bone, skin, cartilage and muscle tissue.[20] Though one long-term goal of 3D bioprinting technology is to reconstruct an entire organ, there has been little success in printing fully functional organs.[21] Unlike implantable stents, organs have complex shapes and are significantly harder to bioprint. A bioprinted heart, for example, must not only meet structural requirements, but also vascularization, mechanical load, and electrical signal propagation requirements.[22] Israeli researchers constructed a rabbit-sized heart out of human cells in 2019.[23]

In 2022, first success of a clinical trial for a 3D bioprinted transplant that is made from the patient's own cells, an external ear to treat microtia,[24] was reported.[25]

Cultured meat

Bioprinting can also be used for cultured meat. In 2021, a steak-like cultured meat, composed of three types of bovine cell fibers was produced. The Wagyu-like beef has a structure similar to original meat.[26][27]

Impact

3D bioprinting contributes to significant advances in the medical field of tissue engineering by allowing for research to be done on innovative materials called biomaterials. Biomaterials are the materials adapted and used for printing three-dimensional objects. Some of the most notable bioengineered substances are usually stronger than the average bodily materials, including soft tissue and bone. These constituents can act as future substitutes, even improvements, for the original body materials. Alginate, for example, is an anionic polymer with many biomedical implications including feasibility, strong biocompatibility, low toxicity, and stronger structural ability in comparison to some of the body's structural material.[28] Synthetic hydrogels are also commonplace, including PV-based gels. The combination of acid with a UV-initiated PV-based cross-linker has been evaluated by the Wake Forest Institute of Medicine and determined to be a suitable biomaterial.[29] Engineers are also exploring other options such as printing micro-channels that can maximize the diffusion of nutrients and oxygen from neighboring tissues.[30] In addition, the Defense Threat Reduction Agency aims to print mini organs such as hearts, livers, and lungs as the potential to test new drugs more accurately and perhaps eliminate the need for testing in animals.[30]

See also

| Vikilugʻatda bioprinting nomli maqola mavjud. |

- 3D printing § Bio-printing

- Cultured meat

- Ethics of bioprinting

- Magnetic 3D bioprinting

- Regenerative medicine

References

- ↑ "Bone and Joint Diseases in Present and Future". Fukuoka Igaku Zasshi = Hukuoka Acta Medica 108 (1): 1–7. January 2017. PMID 29226660.

- ↑ 2,0 2,1 2,2 "Printing Technologies for Medical Applications". Trends in Molecular Medicine 22 (3): 254–265. March 2016. doi:10.1016/j.molmed.2016.01.003. PMID 26856235.

- ↑ "Bioprinting scale-up tissue and organ constructs for transplantation". Trends in Biotechnology 33 (7): 395–400. July 2015. doi:10.1016/j.tibtech.2015.04.005. PMID 25978871.

- ↑ 4,0 4,1 4,2 Bioprinting: Principles and Applications. Singapore: World Scientific Publishing Co, 2015. ISBN 9789814612104.

- ↑ 5,0 5,1 "A sweet solution for replacing organs". Scientific American 308 (4): 54–55. 2013. doi:10.1038/scientificamerican0413-54. https://bioengineering.rice.edu/uploadedFiles/Bioengineering/The_Big_Picture/scientificamerican0413-54.pdf. Qaraldi: 17 February 2016.3D bioprint]]

- ↑ 6,0 6,1 "3D bioprinting of tissues and organs". Nature Biotechnology 32 (8): 773–85. August 2014. doi:10.1038/nbt.2958. PMID 25093879.

- ↑ Manba xatosi: Invalid

<ref>tag; no text was provided for refs namedYoo - ↑ Basic Dental Materials. JP Medical Ltd, 2015. ISBN 9789352500482.

- ↑ „3D Printing Technology At The Service Of Health“. healthyeve. 2016-yil 14-sentyabrda asl nusxadan arxivlangan. Qaraldi: 2016-yil 4-avgust.

- ↑ 10,0 10,1 "Towards preserving post-printing cell viability and improving the resolution: Past, present, and future of 3D bioprinting theory". Bioprinting 11: e00034. 2018. doi:10.1016/j.bprint.2018.e00034. ISSN 2405-8866. http://home.ku.edu.tr/~mmuradoglu/LepowskyEtAlBioprinting2018.pdf.

- ↑ "Development of 3D bioprinting: From printing methods to biomedical applications". Asian Journal of Pharmaceutical Sciences 15 (5): 529–557. September 2020. doi:10.1016/j.ajps.2019.11.003. PMID 33193859. PMC 7610207. //www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=7610207.

- ↑ "3D bioprinting for biomedical devices and tissue engineering: A review of recent trends and advances". Bioactive Materials 3 (2): 144–156. June 2018. doi:10.1016/j.bioactmat.2017.11.008. PMID 29744452. PMC 5935777. //www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=5935777.

- ↑ 13,0 13,1 Datta, Pallab; Ayan, Bugra; Ozbolat, Ibrahim T. (March 2017). "Bioprinting for vascular and vascularized tissue biofabrication". Acta Biomaterialia 51: 1–20. doi:10.1016/j.actbio.2017.01.035. ISSN 1742-7061. PMID 28087487. http://dx.doi.org/10.1016/j.actbio.2017.01.035.

- ↑ 14,0 14,1 Gupta, Prerak; Mandal, Biman B. (2021-06-12). "Tissue‐Engineered Vascular Grafts: Emerging Trends and Technologies". Advanced Functional Materials 31 (33): 2100027. doi:10.1002/adfm.202100027. ISSN 1616-301X. http://dx.doi.org/10.1002/adfm.202100027.

- ↑ Hinton, Thomas J.; Jallerat, Quentin; Palchesko, Rachelle N.; Park, Joon Hyung; Grodzicki, Martin S.; Shue, Hao-Jan; Ramadan, Mohamed H.; Hudson, Andrew R. et al. (2015-10-30). "Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels" (en). Science Advances 1 (9): e1500758. doi:10.1126/sciadv.1500758. ISSN 2375-2548. PMID 26601312. PMC 4646826. //www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=4646826.

- ↑ Munaz, Ahmed; Vadivelu, Raja K.; St. John, James; Barton, Matthew; Kamble, Harshad; Nguyen, Nam-Trung (March 2016). "Three-dimensional printing of biological matters". Journal of Science: Advanced Materials and Devices 1 (1): 1–17. doi:10.1016/j.jsamd.2016.04.001. ISSN 2468-2179. http://dx.doi.org/10.1016/j.jsamd.2016.04.001.

- ↑ Devillard, Raphaël; Pagès, Emeline; Correa, Manuela Medina; Kériquel, Virginie; Rémy, Murielle; Kalisky, Jérôme; Ali, Muhammad; Guillotin, Bertrand; Guillemot, Fabien (2014), „Cell Patterning by Laser-Assisted Bioprinting“, Methods in Cell Biology (inglizcha), Elsevier, 119: 159–174, doi:10.1016/b978-0-12-416742-1.00009-3, ISBN 978-0-12-416742-1, PMID 24439284, qaraldi: 2021-10-27

- ↑ "Bioresorbable airway splint created with a three-dimensional printer". The New England Journal of Medicine 368 (21): 2043–5. May 2013. doi:10.1056/NEJMc1206319. PMID 23697530.

- ↑ "Tissue-engineered autologous bladders for patients needing cystoplasty". Lancet 367 (9518): 1241–6. April 2006. doi:10.1016/S0140-6736(06)68438-9. PMID 16631879.

- ↑ "3D bioprinting and its in vivo applications". Journal of Biomedical Materials Research Part B: Applied Biomaterials 106 (1): 444–459. January 2018. doi:10.1002/jbm.b.33826. PMID 28106947.

- ↑ "Implementations of 3D printing in ophthalmology". Graefe's Archive for Clinical and Experimental Ophthalmology 257 (9): 1815–1822. September 2019. doi:10.1007/s00417-019-04312-3. PMID 30993457.

- ↑ "3D bioprinting for cardiovascular regeneration and pharmacology". Advanced Drug Delivery Reviews 132: 252–269. July 2018. doi:10.1016/j.addr.2018.07.014. PMID 30053441. PMC 6226324. //www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=6226324.

- ↑ „Israeli scientists create world's first 3D-printed heart using human cells“. NBC News (2019-yil 19-aprel). Qaraldi: 2019-yil 20-aprel.

- ↑ „A Multicenter, Single Arm, Prospective, Open-Label, Staged Study of the Safety and Efficacy of the AuriNovo Construct for Auricular Reconstruction in Subjects With Unilateral Microtia“. clinicaltrials.gov (2021-yil 15-oktyabr). Qaraldi: 2022-yil 19-iyul.

- ↑ Rabin, Roni Caryn „Doctors Transplant Ear of Human Cells, Made by 3-D Printer“. The New York Times (2022-yil 2-iyun). Qaraldi: 2022-yil 19-iyul.

- ↑ „Japanese scientists produce first 3D-bioprinted, marbled Wagyu beef“. New Atlas (2021-yil 25-avgust). Qaraldi: 2021-yil 21-sentyabr.

- ↑ "Engineered whole cut meat-like tissue by the assembly of cell fibers using tendon-gel integrated bioprinting". Nature Communications 12 (1): 5059. August 2021. doi:10.1038/s41467-021-25236-9. PMID 34429413. PMC 8385070. //www.pubmedcentral.nih.gov/articlerender.fcgi?tool=pmcentrez&artid=8385070.

- ↑ „Creating Valve Tissue Using 3-D Bioprinting“. ASME.org. American Society of Mechanical Engineers (2013-yil may). Qaraldi: 2016-yil 17-fevral.

- ↑ "Evaluation of hydrogels for bio-printing applications". Journal of Biomedical Materials Research. Part A 101 (1): 272–84. January 2013. doi:10.1002/jbm.a.34326. PMID 22941807.

- ↑ 30,0 30,1 Manba xatosi: Invalid

<ref>tag; no text was provided for refs namedcooper

Further reading

- "To Bioprint or Not to Bioprint". North Carolina Journal of Law and Technology 17: 123–78. 2015. http://ncjolt.org/to-bioprint-or-not-to-bioprint-2/. Qaraldi: 2019-01-12.3D bioprint]]

- "Patenting Bioprinting". Harvard Journal of Law and Technology Digest 29. May 7, 2015.

- Stem Cell Biology and Tissue Engineering in Dental Sciences. Elsevier, 2014, 2014-11-27. ISBN 9780123971579.